Framework for Synchronization of Sales Operations & Planning

Framework for Synchronization of S&OP with advance functions like CPFR and BI to increase efficiency:

Are you doing S&OP properly

S&OP is single most critical competitive weapon that can ensure profitability with right selection of the channels and products for the right customers. But often it is found that the S&OP is not prepared or improved in the way it should be. It may happen because of inappropriate ways or improper choice of the tools used to prepare S&OP making it more cumbersome and laborious. The research (Joseph, 2009) shows that 70% of the organizations will be changing their technology and are on the verge of enhancing their S&OP process in near future. It indicates that the S&OP needs to be improved and enhanced continuously and is necessary for the organization. At the same time, the opportunities and threats related to S&OP should not be overlooked.

The case Elkay Manufacturing studies the adverse effects of competitive environment in the market. The need for improvement made the Elkay managers think about the alternate ways to improve the organizational performance in the market by increasing the involvement of the top management. Finally it was revealed that S&OP provided a “one-plan process” which was the key for the success revealing the important principles for S&OP, which can be followed by an organization to strengthen existing S&OP as follows-

1) Top management is the one who should lead the S&OP implementation and assessment. Employees in the organization must be aware of S&OP & their roles. Executive S&OP champion must be an influential personality and must have experience in demand or supply management at higher level in the organization.

2) Resource effectiveness must be based on the multi SBU combination consisting of supply chains with the focus on the profit optimization.

3) S&OP document must be used for each and every process requiring the data about sales/operations or financial plans. It must be used as a master document in the organization. It should not be redundant or substitutable.

4) Accurate data must be used or obtained by using formatted data obtained from shipping schedules, forecasted sales, warehousing, production or from other operational management processes in the organization.

5) Use of collaborative platforms increasing the frequency of the interaction between the people to share the structured information is necessary for success of S&OP and proper maintenance of master data for getting accurate output.

S&OP & other advanced functions and tools

With the advent of the technology and revolution in distribution and logistics, Sales and Operation Planning needs to be combined with other application functions to improve the performance of the organization in the view of the increasing competition.

Synchronization with CPFR

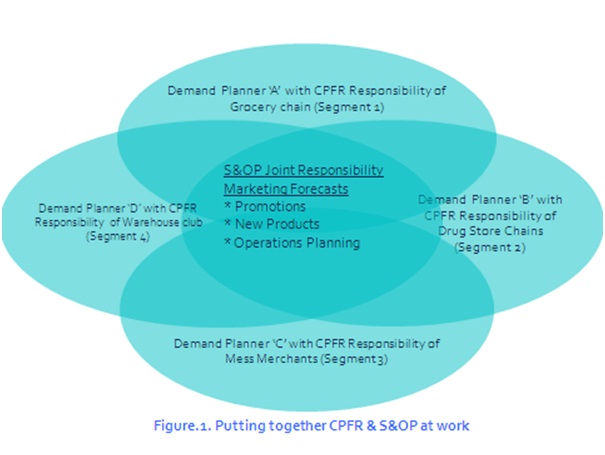

In CPFR the burden of replenishment is on the collaborative partnership of the customer and the supplier. Thus, the retailer’s point-of-sales data (POS) data is used for forecasting. Promotions on sales, exception items, major customer relationship maintenance, etc. issues are handled collaboratively & resolved. When it comes to organization of supplier we can say that S&OP plays a major role in breaking down internal barriers. Thus these two functions can work simultaneously to increase the Supply chain efficiency.

Synchronizing CPFR and S&OP activities will lead to the sharing of information from both the functions and input to each other for better performance. The accurate forecasts using POS data and periodic update about inventory from CPFR function is used as input for the S&OP activities. The market trends can be studied at CPFR end to use it as the indicator of market conditions. The decisions taken at the S&OP are then implemented at retailer levels like promotions, operations management related decisions, etc.

The monthly schedule of CPFR and S&OP must be tightly coordinated and coherently maintained by adhering them together. Week 1 activities of CPFR activities must adhere to week 1 activities of S&OP also Week 2 activities of CPFR activities must adhere to week 2 activities of S&OP and so on. The schedules of both functions must be aggressively adhered to get efficient output.

The demand planners who are involved in the CPFR process and dealing with different chains or customer group have to participate in the joint responsibility of S&OP so that the data collection for demand management is uniform for a particular segment with no variations and can be aggregated to calculate the aggregate demand and corresponding supply capacity at S&OP level as shown in fig.1.

The study conducted (Williams) on CPFR and S&OP synchronization suggests that in only 10 months, the forecast accuracy was improved from 27% to 70%. It suggests that the efficiency of the organization increases with this potent combination of CPFR and S&OP.

Optimization of Output using BI tool

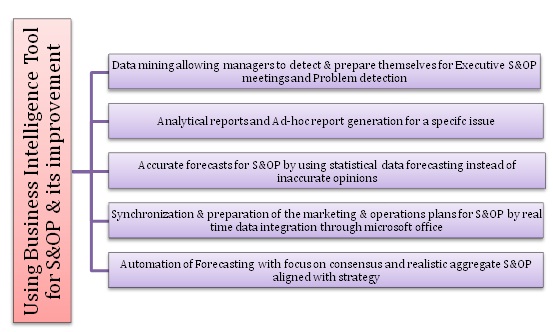

BI tool can be used by executives involved in S&OP process for the efficient use of data spread in the organization by analyzing it.

Advantage of BI over ERP: Unlike the occurrence of the different number under the same heading in ERP, BI assures that the data used across the organization is same. Importantly the use of single value of a KPI or component helps the organization to reduce the conflicts during S&OP. Multiple values in ERP may have a negative effect on the improvement efforts of S&OP by the organization.

Also ERP does not provide the options such as slicing and dicing, drilling down and across the wide database to filter out the information and generate the useful reports. These options are provided in the BI tool. Visualizations in the dashboards makes BI more useful tools for managers preparing for S&OP meetings.

Figure 2. Using BI for S&OP and its improvement

BI allows communicating and helping people; the most important part of the S&OP. Business intelligence empowers employees who are involved in the S&OP process. It eventually suggests fewer problems for S&OP interlock making it easier to arrive at consensus during S&OP.

Framework for implementation of CPFR and BI in combination with S&OP:

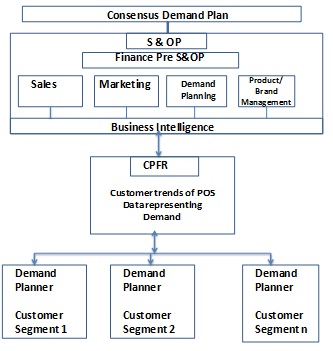

The system with the S&OP can be improved greatly with the implementation of the CPFR and BI. Quite a few researches have been done on the synchronization of the CPFR and S&OP.

Figure. 3. Monthly Synchronized Schedule of S&OP & CPFR with the help of BI

At the same time synchronization of BI tool with these functions increases the efficiency of the system impressively. The suggested framework is as shown in figure. 3.

CPFR schedules must be in sync with the monthly cycles of the S&OP meeting and demand-supply management. The demand planning for each customer segment should be taken into consideration using the CPFR collaboration with Retailers. POS data should form the basis of the forecasts.

Business Intelligence tool should be implemented to collect the data (online servers).

Functional divisions like marketing, operations, Demand Planning, etc. should use the same data obtained by BI system. The Finance Pre-S&OP should be carried out for the reconciliation purpose. The formal S&OP meeting and aggregate level demand representation will make the organization capable of generating the consensus demand plan which can be used for the further MRP (Material Resource) Planning Procedures.

Conclusion

S&OP is crucially important process for every organization. But if it is not carried out properly and hidden challenges are ignored then it becomes difficult to achieve the desired results. So the improvement of the S&OP process must be continuous for the sustainable operational management. At the same time various functions that can be integrated with S&OP for improvement in the performance of the organization must be combined and synchronized with S&OP. This will make sure that with the change in the technology the organization is changing & is capable of enhancing its S&OP process for better & sustainable performance.

References

Bower, P. (2005). 12 Most Common Threats to Sales and Operations Planning Process. Journal of Business Forecasting Methods & Systems, Vol. 24, No. 3.pp.4-14.

Stahl, R.A. (1999), Sales And Operations Planning – A Fundamental That Still Works.APICS International Conference Proceedings

Wood, C.B., & Boyer, J.E. Jr. (2002). Sales and Operations Planning at Elkay Manufacturing: A Case Study. APICS International Conference Proceedings

Oliva, R., & Watson, N. (2006). Cross-Functional Alignment in Supply Chain Planning: A Case Study of Sales and Operations Planning. Harvard Business Working Paper. No. 07-058

Mazel, J. (2009). New research tells how to put muscle into S&OP Process, Supply chain strategy

Williams, M.K., Combining CPFR with S&OP to attain optimum customer service. Williams supply chain group

A Guide to CPFR Implementation.(2001, April). Report by Accenture, ECR Europe.

S&OP Process is a Strategic Driver for Improving Business Performance. (2008, December). Research Brief, Aberdeen Group.

McCarthy, T. and Golicic, S. (2002), “Implementing Collaborative Forecasting to Improve Supply Chain Performance,” International Journal of Physical Distribution & Logistics Management. 32:6, p. 431-45

Baumann, F. (2010), The Shelf Connected Supply Chain : Strategically Linking CPFR with S&OP at the Executive Level. Journal of Business Forecasting

This article has been co-authored by Akshay Jadhao and Sneha Ramteke from IIM, Kozhikode.

Views expressed in the article are personal. The articles are for educational & academic purpose only, and have been uploaded by the MBA Skool Team.

If you are interested in writing articles for us, Submit Here

Share this Page on:

What is MBA Skool?About Us

MBA Skool is a Knowledge Resource for Management Students, Aspirants & Professionals.

Business Courses

Quizzes & Skills

Quizzes test your expertise in business and Skill tests evaluate your management traits

All Business Sections

Write for Us