Engineer-to-Order - Definition, Importance, Steps & Example

What is Engineer-to-Order?

Engineer to order is a type of manufacturing process in which a product is designed, engineered and finished after an order has been received. The product is engineered to meet the specifications desired by the received order. The representatives of the customer company engage with the manufacturing team throughout the process to ensure that each and every specification is met. The engineer to order process is used for very complex products or very specialized products. Engineer to Order is also referred to as Make to Order at times.

Importance of Engineer to Order

Many a times customers want a specific product which may or may not be available readily in the market. So engineer to order is a process in which the manufacturing only starts when the manufacturer understands the exact customer demand and specifications, then the product is made. This increases the customer satisfaction and manufacturer also gets the proper value. Engineer to order is very important in the B2B scenarios than B2C but there are certain scenarios like furniture where engineer to order may be used.

Challenges with ETO (Engineer-to-order processes)

• The entire process has to be carefully planned as the product to be manufactured is complex

• High level of customer participation in the entire process

• A robust designing process required

• Lot of confusion is generally there between company and the consumers

• Several revisions may be required to finalize the engineering specifications

• Costs of the entire process are very difficult to be predicted

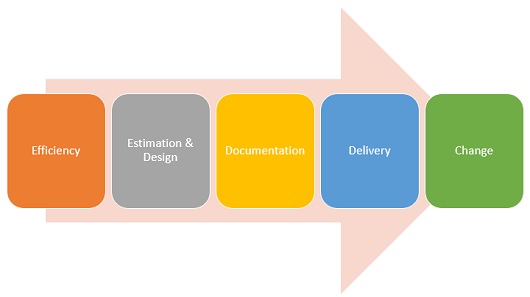

5 Steps for an efficient ETO process

1. Develop a consistent and efficient part numbering process

2. Ensure a robust estimation and designing process

3. Create proper documentation bills for each item, subpart, assembly etc. to be used to manufacture the product

4. Delivery has to be handled as per customer's expectation and location

5. Manage the engineering changes properly

Example of Engineer to Order

ETO model is used in industrial manufacturing processes where the products are complex and costly. ETO process is used by the companies in aerospace manufacturing when they receive any special orders from governments or big companies. ETO model is very common in defense, aerospace and energy industry.

Hence, this concludes the definition of Engineer-to-Order along with its overview.

This article has been researched & authored by the Business Concepts Team. It has been reviewed & published by the MBA Skool Team. The content on MBA Skool has been created for educational & academic purpose only.

Browse the definition and meaning of more similar terms. The Management Dictionary covers over 1800 business concepts from 5 categories.

Continue Reading:

What is MBA Skool?About Us

MBA Skool is a Knowledge Resource for Management Students, Aspirants & Professionals.

Business Courses

Quizzes & Skills

Quizzes test your expertise in business and Skill tests evaluate your management traits

Related Content

All Business Sections

Write for Us