- Articles ›

- Operations and IT ›

- Green Supply Chain Management- Examples and Results Articles

Green Supply Chain Management- Examples and Results

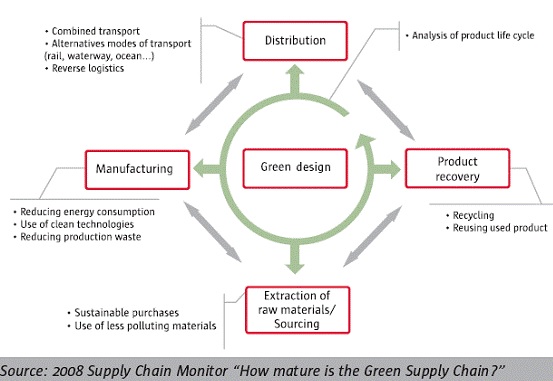

Supply chain management has been historically viewed as a process wherein raw materials are transformed into finished goods and then delivered to consumer. However, in the past few years, the emissions and the waste generated by the traditional supply chains have reached unendurable levels and have become one of the major causes of grievous environmental problems, such as acid rains and global warming. As a result, the need for environmental sustenance has been gaining intensity among the prevalent business practices. In view of the above developments, "Green Supply Chain Management" (GSCM) has managed to seize the raising interest among practitioners and researchers of operations and supply chain management. GSCM covers all stages of a product's life cycle from the planning, production, and distribution phases to the use of goods by the end users and its disposal at the end of product's life cycle. GSCM involves the integration of environmental thinking into supply chain management (SCM). It is an approach that targets the overall optimization of information flows and material flows along the value chain.

Image:pixabay

GSCM = Green purchasing + Green manufacturing/materials management + Green Distribution / Marketing + Reverse logistics.

Customers are increasingly becoming conscious of green practices adopted by various organizations in India. So, organizations need to focus on the optimal employment of resources and energy for creating environmentally sound supply chains. GSCM practices can be classified as GSM practices related to customers and suppliers; environmental management practices within the organization; environment-conscious process designs and goods. These may include several practices namely environmental compliance, commitment of GSCM from senior and middle-level managers, auditing programs, suppliers' certifications from International Organization for Standardization, collaboration with suppliers for environmental objectives, environmental management for suppliers' internal management, company-wide environmental inspections, cooperation with customers for cleaner production and eco-design, training to build supplier environmental management capacity, design of products for reduced consumption of energy and materials, environment-friendly raw materials, design of products for recycle, reuse and recovery of material and component parts and optimization of processes to reduce solid/liquid waste and emission. The need of the hour is to integrate environmentally sound choices into supply-chain practice and research to achieve sustainable growth and development.

GSCM vs Traditional SCM

GSCM and tradition SCM are starkly different at many levels. Traditional SCM is usually driven by the single agenda of economy as its ultimate objective while GSCM takes into account both the ecological as well as economic objectives. SCM outrightly rejects eco-friendly practices whereas GSCM emphasizes green, integrated and ecologically optimized practices. Traditional SCM is more focused on controlling the final product, with no regard to the ensuing harmful effects on environment during distribution and production.

S. No Characteristics Green Supply Chain Management Traditional Supply Chain Management

1 Objectives • Ecological

• Economic Economic

2 Impact on ecology High Low

3 Criteria for selecting suppliers Long-term relationship, Ecological aspects stressed Short-term relationship, suppliers switched frequently

Benefits of Adopting Green Supply Chain Management

Green Supply Chain Management (GSCM) strategies help in reduction of negative impacts on the ecosystems & in improving the condition of the environment. Today’s socio-economic dynamics & regulatory forces are compelling companies to be green & lean in their product sourcing, operational activities, distribution and logistics. Thus, it is becoming increasingly necessary for companies to go for GSCM in order to remain sustainable. Additionally, it is found that by switching to GSCM practices, ceteris paribus, companies can reduce costs by up to 20%. Though, by introducing new technologies companies can help reduce costs much more drastically, the costs of Research & Development is, most of the times, very high, and may not provide adequate returns on investment (ROI). Whereas, in case of GSCM the results are much more reliable. In addition to all that, by raising their green credentials among employees, government authorities, customers and other stakeholders, companies can project a positive brand identity by projecting itself as an organization which protects the environment & ensures sustainable future for all.

McDonald’s, the world’s largest chain of hamburger fast food restaurants, is considered to be one of the pioneers in adopting green practices. It helped its potato supplier in Austria to set up a biogas plant to process all of their solid & liquid wastes accrued from potato production. The gas produced by the plant is used to create heat which in turn is used to preheat the dryer for the French Fries production process. Also, the gas produced is converted into electricity to supply to the public grid. The residue from the conversion process is provided to potato farmers for using it as a fertilizer. Through heat recovery process, which is serving the dryer, electrical energy of 4.2 gigawatt hours a year is produced. Overall, 40% of the facility’s energy requirements are catered to by using this method. Furthermore, recycling of the frying oil (that is left out at the end of frying process) for creating biofuel so as to power its logistical operations, and serving of salads on cardboards instead of using plastic bowls, are some of the positive green initiatives from McDonald’s.

Going green also helps companies to come up with profitable initiatives that can be used to cater to the needs of the Bottom of the Pyramid (BOP). In India, where at least 30% of the population have minimal access to electricity, Coca – Cola came up with solar-powered vending machines which helped it to reach out to more than eighty thousand untapped villages. These machines use insulation materials which help them to run without power for up to 16 hours per day and require power supply only during nights (when it is mostly available).

Another example comes from Hindustan Unilever Ltd., which has a well-formulated recycling program used for eco-friendly disposal of wastes generated at its national headquarters in Mumbai. HUL uses an in-vessel vermi-culture system which converts organic wastes to vermi-compost organic fertilizer & vermi-wash liquid fertilizer. This highly nutritional fertilizer is used to enrich the magnificent lush gardens surrounding the office. The inorganic waste, which mainly comprises cardboard & paper, is sent to recycling units. This helps to reduce the production of greenhouse gases & carbon footprints which would have otherwise been produced by the manufacturers of these products. HUL has also entered into a one-of-its-kind partnership with the poor rag-pickers, which if pursued nation-wide by various companies, can help in substantial reduction of India’s 12k tons of junk which is produced every day. Initially, the HUL partnership program was set up at the stockiest and warehouse levels. The ruptured packs were collected and sorted by rag-pickers and were eventually sold to paper mills. It would have been impossible for municipal corporation to handle such walloping volumes of junk, if it were to do it all by itself. Currently, HUL is focusing on improving the monetary value obtained from the plastic wastes such as discarded sachets and lighter plastic packaging so that rag-pickers are able to sell them and thus, find some economic incentives in picking them up from the streets. For streamlining the process, it has also partnered with a company in Chennai in order to convert flexible plastic wastes into fuel oil at a workable cost. HUL's Pondicherry factory has been successful in using this fuel to power its boilers.

Concluding remarks

Greening of the product supply chain is a novel initiative which not only benefits future generations to come but also the current profitability of the company which proactively uses it. During the recent times there has been a substantial increase in need for organizations to focus on GSCM especially because of increased consensus amongst various stakeholders of the society towards the use of conservative & sustainable practices. Thus, GSCM has found its way in the entire spectrum of supply chain activities like manufacturing, purchasing, materials management, distribution & logistics, and reverse logistics. The lucrative paybacks of having GSCM, have led to these practices being increasingly adopted by corporations worldwide. The specialists of GSCM have formulated better and more pioneering ways for reducing their carbon footprints & green-house-gases (GHG) emissions. Although the high net worth players of various businesses have proved their environmental sensitivity, the usage of GSCM practices in MSME (Micro, Small and Medium Enterprises) has a long way to go. Also, with the increasing correlation being found between the extent of GSCM by the companies and the enhancement of their economic performance and competitiveness, this concept is sure to become a popular trend in the near future.

This article has been authored by Akshay Gajghate & Harsh Dalmia from IIM Shillong

References

1. http://www.redalyc.org/articulo.oa?id=84720408

2. http://www.apo-tokyo.org/00e-books/GP-09_GreenSupplyChain.htm

3. Green supply-chain management: A state-of-the-art literature review, Samir K. Srivastava, International Journal of Management Reviews (2007)

4. A green supply chain is a requirement for profitability, Sameer Kumar, Steve Teichman and Tobias Timpernagel, International Journal of Production Research Vol. 50, No. 5, 1 March 2012, 1278–1296

5. https://www.youtube.com/watch?v=w-kdqxdqdr0

6. http://www.coca-colacompany.com/stories/5by20

7. https://www.youtube.com/watch?v=DJ6QGesUWAQ

8. http://www.aboutmcdonalds.com/mcd/sustainability.html

9. http://www.greenbiz.com/news/2010/05/04/potato-power-homes-factories-on-mcdonalds-new-best-practices-list

10. http://articles.economictimes.indiatimes.com/2013-01-22/news/36484680_1_ragpickers-plastic-waste-waste-management

11. http://www.hul.co.in/mediacentre/pressreleases/2012/unilever-reports-on-first-years-progress-against-ground-breaking-sustainable-living-plan-targets.aspx

Views expressed in the article are personal. The articles are for educational & academic purpose only, and have been uploaded by the MBA Skool Team.

If you are interested in writing articles for us, Submit Here

Share this Page on:

What is MBA Skool?About Us

MBA Skool is a Knowledge Resource for Management Students, Aspirants & Professionals.

Business Courses

Quizzes & Skills

Quizzes test your expertise in business and Skill tests evaluate your management traits

All Business Sections

Write for Us