Inventory Shortage Penalty Cost - Definition & Meaning

What is Inventory Shortage Penalty Cost?

Inventory is the stock of materials or finished goods a manufacturer or seller keeps to cater to fluctuations in unanticipated demand from the consumer end. Just as carrying excess inventory results in high cost incurred by the seller, the flipside is the inventory shortage cost. When the supplier runs out of the particular product in demand occurring within a definite lead time, a stock-out of the product occurs and he /she has to incur penalty cost of lost sales. This is what inventory cost signifies.

Inventory shortage cost is, however, difficult to quantify exactly. Usually, an approximate figure is arrived at after considering several parameters viz. lost customer, lost sales, stock-out penalties and disputes in contract. In some cases though, inventory shortage does not cost an immediate loss in sales or profit. The seller will commit to deliver the product within a particular lead time. The cost incurred in that case is the ‘back-order cost’.

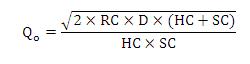

Thus for an operations manager, shortage cost becomes very important in deciding the optimal order quantity for known demand. A trade-off has to be made between re-order cost, inventory holding cost and shortage cost, to minimise all the three. In such a case, the optimal order quantity is given by:

where, D = periodic demand, RC = re-ordering cost, HC = inventory holding cost, SC = inventory shortage cost.

Hence, this concludes the definition of Inventory Shortage Penalty Cost along with its overview.

This article has been researched & authored by the Business Concepts Team. It has been reviewed & published by the MBA Skool Team. The content on MBA Skool has been created for educational & academic purpose only.

Browse the definition and meaning of more similar terms. The Management Dictionary covers over 1800 business concepts from 5 categories.

Continue Reading:

What is MBA Skool?About Us

MBA Skool is a Knowledge Resource for Management Students, Aspirants & Professionals.

Business Courses

Quizzes & Skills

Quizzes test your expertise in business and Skill tests evaluate your management traits

Related Content

All Business Sections

Write for Us