- Articles ›

- Operations and IT ›

- The World of Smart Manufacturing Articles

The World of Smart Manufacturing

Over the last 2 decades the two most important things have driven business. The first one is improvement & rapid development of high-tech computers. The second one is the penetration & faster speeds of internet. This has revolutionized how businesses are done worldwide. Phones has been replaced by mobiles, paperwork has been replaced by cloud documentation and processes have been automated across industries.

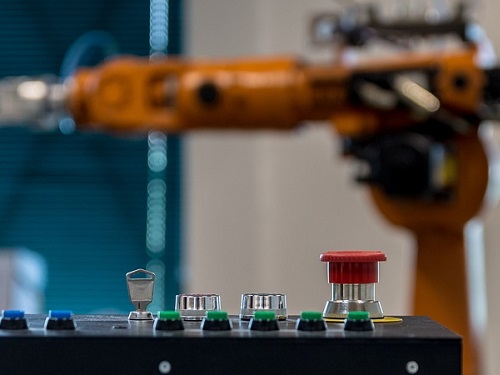

Apart from the service industry or white-collared jobs, there has been a significant intervention of technology in manufacturing. The use of technology, robotic tools, flexibility in training using technology and rapidly flexible solutions is now being adopted. This is also known as smart manufacturing. The concept of smart factory uses technology, simulation software, networking solutions, online integration with hardware etc.

Image: pixabay

Some of the key drivers of smart manufacturing include big data, industrial devices with internet, and robotics tools etc. These solutions help in a flexible manufacturing process which accommodates rapid changes, instant monitoring, enhanced security etc.

Big data in smart manufacturing is a concept to store all information & data in a computer. This data is compiled and uses several software to monitor data real-time, compare performances, create trends, evaluate efficiency etc. Using big data by a manufacturer helps them understand the demand, seasonality, output required, inventory management etc.

Advanced robotics helps in precision, fast, accurate, heavy manufacturing which increases output & efficiency. Smart manufacturing uses advanced robotics which replaces human workforce for performing repetitive work tirelessly. Also, a smart factory connects all tools & devices, and uses internet to store data on cloud & servers. Such enterprise solutions enable manufacturers to gather data at each level of production, monitor progress and see production output.

Another important business which is developed as a part of smart manufacturing is 3D printing. This technology uses creating tangible materials or goods or prototypes simply by printing them in 3D on materials. These can be done in a small scale but with the output design being very accurate, precise, high in quality & rapid production.

Smart manufacturing also focuses on improving working standards of workers. It helps in

- improving safety standards by monitoring the environment.

- ensure people are not exposed to harmful substances.

- keeping a check on product quality which otherwise maybe missed by humans.

- provide a real-time solution to overcome any human errors.

- replace mundane repetitive jobs so that workers can focus on qualitative manufacturing.

Smart manufacturing is a very broad term, and it helps in decreasing defective products, enables faster production of prototypes, and lowers the cost of production. From large manufacturing plants to small factories, all companies are benefitted by smart manufacturing, and with the advent of technology, this adoption will only keep on increasing.

The article has been authored by the editorial team. The content on MBA Skool has been created for educational & academic purpose only.

If you are interested in writing articles for us, Submit Here

Share this Page on:

What is MBA Skool?About Us

MBA Skool is a Knowledge Resource for Management Students, Aspirants & Professionals.

Business Courses

Quizzes & Skills

Quizzes test your expertise in business and Skill tests evaluate your management traits

All Business Sections

Write for Us