- Articles ›

- Operations and IT ›

- Role Of Information Technology In Supply Chain Optimization Articles

Role Of Information Technology In Supply Chain Optimization

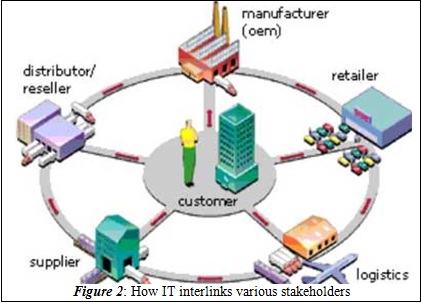

The use of information technology (IT) is considered a prerequisite for the effective control of today’s complex supply chains. Because, today companies are often not considered independent entities, but parts of multi-company, multi-echelon networks, i.e. supply chains, delivering goods and services to the final customer.

Companies today are under pressure to better manage the supply chain and to improve efficiency and logistics operations while remaining responsive to changing market conditions and customer demands. As a result, organizations need to adopt IT to support their supply chains and increase their efficiency by achieving tighter cooperation over the supply-chain.

Importers and exporters need to know where their product is. Lenders need to know when and how to pay for it. Innovative companies have sprung up to harness the power of the IT, making it easier than ever for logistics managers to track and manage international shipments, and to serve their changing needs as they reach ever further across the globe to source goods. Companies such as Home Depot, Xerox and Sears already use on-demand, Web-based data hubs to identify where their goods are in real time, and if delays along the way should be corrected to avoid broader supply chain disruptions and expensive recovery work.

TYPE OF ‘IT’ USE FOR OPTIMIZING SCM

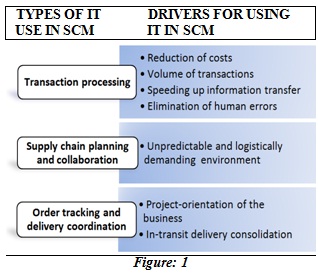

The use of IT for optimizing SCM can be divided into (Ref. Figure 1):

- Transaction processing

- Supply chain planning and collaboration

- Order tracking and delivery coordination

Transaction processing stands for the use of IT for increasing the efficiency of repetitive information exchanges between supply chain partners. In this type of IT use the exchanged information is typically related to such tasks as order processing, billing, delivery verification, generating and sending dispatch advices, and producing order quotes.

Supply chain planning and collaboration represents the use of IT for sharing planning-related information such as demand forecasts and other demand information, inventory information, and production capacity information, with the intention of increasing the effectiveness of the supply chain.

Order tracking and delivery coordination refers to the monitoring of individual orders or shipments, which may consist of components or final products, with the aim of coordinating their delivery or conveying timely information of their location.

HOW ‘IT’ HAS OPTIMIZED THE SCM

IT plays instrumental role in bringing together multiple technologies and integrating them to optimize various scenarios in SCM. For instance when “Radio Frequency Identification” (RFID) is used with IT, the combination promises to enable an automatic collection of supply chain data for optimization purposes. The above combination makes it possible to implement a finely grained and immediate collection of data, which in turn enables more detailed and precise analyses on the “Business Intelligence” (BI) side.

A connection of RFID, IT & BI has powerful business potential that goes well beyond incremental operational improvements. The combination for tracking & tracing, and sensor technologies additionally enables the identification and localization of root causes for quality issues. Sensor data such as abrasion, temperature, humidity, or brightness can be measured automatically for each transport unit and stored on the RFID chip. Later this data is made readily available by IT for aligning the flow of goods with the actual demand.

The pursued objectives are reducing storage space at the “Global Distribution Centres” (GDC) while curbing the risk of out-of-stock situations. In an optimal scenario, goods arriving at the GDC can be directly forwarded to the retailers without stocking (Cross-Docking).

The benefits of a combination of IT, RFID and BI on the manufacturer’s side lead to efficiency gains within production environments. Overall, the results indicate that it has powerful business potential that goes well beyond incremental operational improvements.

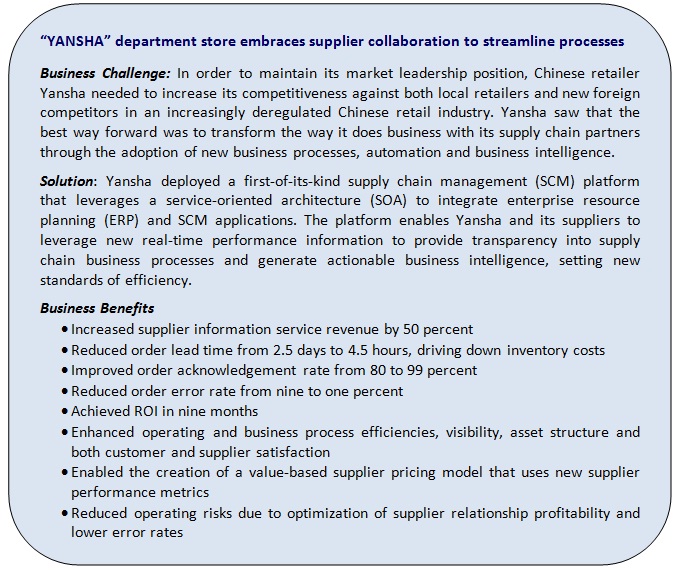

CASE STUDY

'IT' AS AN ENABLER FOR A ‘GREEN SUPPLY CHAIN'

The focus on optimization and sustainability has resulted in a growing need for integrating environmentally sound choices into supply chain management research and practice.

Patrick Penfield of the Whiteman School of Management defines Green Supply Chain Management (GSCM) as "the process of using environmentally friendly inputs and transforming these inputs into outputs that can be reclaimed and re-used at the end of their lifecycle thus, creating a sustainable supply chain.”

IT Enables Green Initiatives

In most new initiatives adopted by organizations, IT has played a pivotal role in ensuring the chances of success and reaping the expected benefits.

Contributions of IT in GSCM can be viewed from two different perspectives.

Hardware Perspective - Optimizing hardware resources to support the business.

Technology providers are innovating and developing energy efficient solutions that have a more favourable impact on the environment. Few solutions are:

- Right-Sizing IT infrastructure

- Re-architecting Data processing and Storage operations

- Leveraging shared infrastructure

- Adopting a lifecycle approach to the retiring of IT waste

Software perspective - Streamlining / Transforming Business Processes.

IT can enable more effective supply chain planning, execution and collaboration, thereby reducing resource requirements.

- Green Supply Chain Planning: IT can optimize transportation planning routes and ensure that goods/services are delivered in the most energy efficient and cost- effective manner.

- Green Supply Chain Collaboration: Collaborative Transport Management (CTM) goes hand-in-hand with GSCM. IT facilitates the involvement of all partners in supply-chain and help organizations achieve better utilization of transportation assets and reduce overall energy requirements

PROMINENT CHANGES IN ‘IT’ ENABLED TRADE SCENARIOS

As globalization of trade gets a firmer foothold, the tendency to rely on ‘Letters Of Credit’ (LOC) is waning and other forms of cross-border payments and financing are starting to emerge in place of LOC, with open account payment terms becoming much more common. In the absence of LOC, banks need other kinds of information to gain greater visibility into their collective risk.

Banks will now accept document substitutes, such as an “acknowledged purchase order” as part of an overall picture that also includes the bank’s relationship with the importer, delivery performance history and the general trade relationship between the seller and importer. One way of establishing and monitoring all of this information is through an online system that allows banks to see this data immediately and securely via the Web. Moving to “IT-enabled” open account terms better reflects the movement in international trade payments.

Yet another improvement offered by reliable, real-time IT enabled supply chain is that it provides the basis for in-transit inventory financing, by providing access to electronic trade documents and on-line visibility to the actual movement of inventory.

BENEFITS OF INTEGRATING THE SUPPLY CHAIN

- Standardised production, including improved quality control, shorter production time, greater efficiency.

- Simplified supply chain process, including control over suppliers, improved process cycle time, close cooperation relationships, improved supply chain efficiency, raw materials on time for suppliers.

- Process automation, including reduced errors, capability to obtain and exchange real time information.

- Improved purchasing process, including reduced arrangement and handling times, shortened response time for purchasing, improved order process speed, reduced labour costs.

- Reduced stocking including reduced risk, reduced stock capital costs, reduced unused raw material stock.

- Improved payment process including faster payment operation, lower interest rate, and lower credit risk.

- Improved distribution process, including delivering on time, reduced delivery enquiring time, improved distribution management.

- Improved global competitiveness including global order opportunities.

CONCLUSION

A competitive firm has to have the ability to acquire the goods and services it needs just when and where it needs them, at a favourable price, and with acceptable payment and delivery terms. A competitive firm needs to directly manage the flow of goods through its distribution networks in a cost-effective manner. Organizations have come to realize that they can achieve this by integrating their supply chains.

The adoption of IT to support the supply chain management can be seen either as a way to provide efficiency savings, or as a strategic response either driven by necessity or due to competitive pressure. Therefore, IT implementations deliver many benefits like standardized production, optimized supply chain process, and automated process.

This article has been authored by Gurkirat Singh from NITIE.

Views expressed in the article are personal. The articles are for educational & academic purpose only, and have been uploaded by the MBA Skool Team.

If you are interested in writing articles for us, Submit Here

Share this Page on:

What is MBA Skool?About Us

MBA Skool is a Knowledge Resource for Management Students, Aspirants & Professionals.

Business Courses

Quizzes & Skills

Quizzes test your expertise in business and Skill tests evaluate your management traits

All Business Sections

Write for Us