- Articles ›

- Operations and IT ›

- How Do Companies Decide When To Make And When To Outsource? Articles

How Do Companies Decide When To Make And When To Outsource?

Procurement has emerged as one of the most powerful ways of enhancing the economic performance of an organization. This has led to a greater emphasis on the concept of strategic procurement, of which sourcing and outsourcing are two components. Sourcing is defined as the procurement of products and services from sources that are external to the organization. Outsourcing, on the other hand, refers to the transfer or subcontracting of the management and/or day to day execution of an entire business function to an external service provider.

Outsourcing is a process in which a company delegates some of its in-house operations or processes to a third party, which has the capability to perform that function better than the parent company and at a lower cost. Hence, outsourcing is based on the continued drive towards specialization. Among the activities outsourced are: Book keeping, Business consultancy, Data entry, Proof reading and editing etc.

For example, a car maker needs a variety of nuts and bolts. Instead of manufacturing these components themselves, the company may outsource their production to some other firm that specializes in the manufacture of nuts and bolts. By this strategy, the car maker can focus on its core functions – such as the designing the car and the engine – and at the same time obtain good quality smaller components at low costs.

The attitude towards outsourcing is mixed – in the 1990s most companies started outsourcing manufacturing. Although initially successful, they soon met with difficulties. Nike’s policy of outsourcing production had caused it to grow at an annual rate of 20% per annum in the 1990s. However, in 2001 Nike reported an unexpected fall in profits due to inventory build-up in some products and shortages of some others.

Till date no company has been able to design a foolproof method to outsource successfully. It still remains a strategic decision that has to be taken in the light of several influencing factors.

Benefits of Outsourcing:

Focus on Core Competency: Companies typically outsource less critical and non-core functions. This leaves it with resources to focus on its area of expertise.

Gaining Outside Knowledge: External providers, being experts in their respective fields, provide inputs to improve products and processes.

Cost Savings by Economies of Scale: Strategic outsourcing (outsourcing the manufacturing of key components) leads to cost savings for companies, as suppliers can achieve economies of scale by aggregating orders from many buyers. Almost 85% of Wal-Mart's merchandise is made abroad, mostly in China. Goods worth around $15 billion sold at Wal-Mart are made in China. These Chinese suppliers have been able to provide startling price cuts. For example, portable DVDs with 7" LCD screens dropped to half when Wal-Mart found a Chinese factory to build them in huge quantities.

Risk Pooling: Third-party providers face the aggregate demand of several buyers and this reduces uncertainty through the risk-pooling effect.

Increased Flexibility: Outsourcing enables companies to react to changes in consumer demand better and gain access to new technologies and innovation faster.

Reduce Capital Investment: By outsourcing, companies do not need to invest in all its functions. Further, service providers can make required investments readily as their cost is implicitly shared by many buyers.

Risks and Disadvantages of Outsourcing:

Loss of Competitive Knowledge: Outsourcing of critical components to suppliers may lead to loss of competitive advantage. Specialized knowledge of one company may get transferred to competitors, when both outsource to the same supplier. When IBM entered the PC market in 1981, it outsourced manufacturing of its components to Intel. In 3 years IBM was able to replace Apple as the largest supplier of Personal Computers. However, companies such as Compaq were able to enter the market soon, by utilizing the same suppliers as IBM.

Increased Transportation Costs: If the distance between client and provider is large, delivery costs can rise substantially.

Loss of Control: Outsourcing transfers the control over manufacturing to some third party. Thus the client loses direct control over production.

Creating future Competition: If core competencies are outsourced, suppliers can turn into competitors for the buyer in future. This was faced by Intel. Intel outsourced its core competency, chip production to AMD when it faced production shortages. Within a few years AMD started manufacturing its own chips.

Conflicting Objectives: Buyers and suppliers generally have different objectives. Buyers look at gaining increased flexibility and adjusting production rates to changing demands by outsourcing. Contrarily, suppliers want a long-term commitment from the buyer to purchase fixed quantities.

Poor Relationship with Third-Party Provider: At times, poor relationship between the client and the provider may cause a particular outsourcing deal to fail. The reasons may be poor communication, poor cultural fit and lack of trust.

Buy / Make Decision Framework:

One of the most strategically significant decisions that firms have to take is what to produce in-house and what to outsource. There are several considerations that must be weighed to arrive at the best decision. The buy/make decision involves a trade off. By making rather than buying, a firm is at a risk of losing alternative sources, design flexibility and access to technological innovations. Similarly, buying products instead of making them may lead to loss of competitive advantage and high transaction costs. The decision should be taken considering the following dimensions:

1. Independence of Knowledge and Capacity of the Firm and the Type of Product

Companies outsource to external providers mainly for two reasons: 1)Dependency on Capacity: The company has the knowledge and skills needed to produce a component, but outsources production as it does not have the requisite capacity. 2) Dependence on Knowledge: The company does not have the knowledge and skills needed to produce components, hence it outsources to third-party providers that have the capabilities.

For Example, Toyota has the knowledge as well as capacity to produce its engines. Hence all its engines are produced internally. It has the knowledge and designs all its components. But it depends on its suppliers’ capacity to manufacture them and 70% of the components are outsourced. It has both knowledge and capacity dependence on its external suppliers for the vehicle electronic systems.

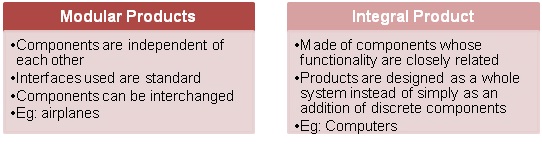

There is a need to understand the product and its architecture thoroughly in order to ascertain what to make and what to outsource. Here products can be classified into two categories:

|

Product |

Dependence on knowledge and capacity |

Independent for knowledge and dependence on capacity |

Independent for knowledge and capacity |

|

Modular |

Outsourcing is risky |

Outsourcing is an opportunity |

Outsourcing will reduce costs |

|

Integral |

Outsourcing is risky |

Outsourcing is an option |

Production should be kept internal |

2. Core Competencies and Strategic Planning:

An organization has to perform a vast range of activities in order to produce goods and services. Out of all the activities, there will be a certain few which the company performs better than most other organizations. These skills, talents and capabilities are the core competencies of the firm, and identify its unique strengths. By common sense, core competencies are the activities that a firm should perform in-house.

Other non-core functions should be outsourced to external service providers, for whom these activities are their respective core competencies. Nike is one of the most successful companies in the athletic shoe industry. Its core competencies are shoe design and merchandising. Hence it outsources almost all of its manufacturing activities, and instead focuses on research and development and on marketing, sales and distribution.

3. Total Lowest Cost

A company may chose to produce internally or outsource based on whichever option costs lowest. For example, In order to reduce costs, Boeing outsourced 70% of the production of its Dreamliner. The increase in outsourcing may have reduced the costs of some components, but this cost has been more than offset by increased re-design costs and expensive delays.

Conclusion:

Outsourcing is essentially a business decision. Considering the complexity of goods and services produced in today’s era, we clearly cannot do without outsourcing. Very few companies in the world have the ability and capacity to excel in each and every task involved in making a product. It is true that some companies have run into difficulties trying to outsource some activities. For example, Dell had initially outsourced its help-desk services to India. However, following complaints that customers could not understand the accent of the Indians, Dell had to back-source its operations to USA. These instances should be viewed as learning stages.

Whenever any new idea is implemented, some time is needed before it can be grasped and implemented effectively. From this particular case, the world has learnt that not only is it necessary to consider the technical and financial viability during outsourcing, but the cultural aspect also needs to be assessed.

If implemented effectively, outsourcing can help a firm achieve substantial cost savings and increase in efficiency. Risks can be avoided by careful planning and evaluation of all parameters that may affect the situation. Failure to foresee potential pitfalls will result in losses for companies. The most important dimension in outsourcing is to determine which of the business activities to outsource and which to retain. To make this decision correctly companies need to identify their core competencies and determine which option costs least. The buy/make decision can also be based on the capabilities of the firm and on whether the product is modular or integral.

This article has been authored by Rubayet Chakraborty & Ahana Chakraborty from NITIE.

Views expressed in the article are personal. The articles are for educational & academic purpose only, and have been uploaded by the MBA Skool Team.

If you are interested in writing articles for us, Submit Here

Share this Page on:

What is MBA Skool?About Us

MBA Skool is a Knowledge Resource for Management Students, Aspirants & Professionals.

Business Courses

Quizzes & Skills

Quizzes test your expertise in business and Skill tests evaluate your management traits

All Business Sections

Write for Us