- Articles ›

- Operations and IT ›

- Best Practices in Supply Chain Management Articles

Best Practices in Supply Chain Management

Supply chain management (SCM) is a set of approaches used to efficiently integrate the “facilities” i.e. suppliers, manufacturers, distribution centres and the “materials” i.e. raw materials, work in progress inventory and finished products so that the product is produced and distributed in the right quantities, to the right locations and at the right time. The implementation of SCM requires dealing with the uncertainties like lead time, breakdowns, weather, local politics, labour conditions etc. inherent in its every step.

Image courtesy of FreeDigitalPhotos.net

SCM processes that are efficient, robust, and closely aligned with company strategy don’t just reduce costs. They also set a company apart and give it an edge in the fight for customers and market share. For these reasons, effective supply-chain management has become increasingly critical to business performance in times both good and bad. It has become a key factor in a company's competitiveness and leading edge organizations are meeting the performance challenge through adopting internet tools, build-to-order-mass customization programs, vendor managed inventory and other productivity initiatives. Understanding the very latest systems, practices and world-class performance is crucial to companies seeking to improve their own supply chain management effectiveness. Let us look at some of the valuable insights into the best practices that leading companies use to design and manage their networks of supply chains.

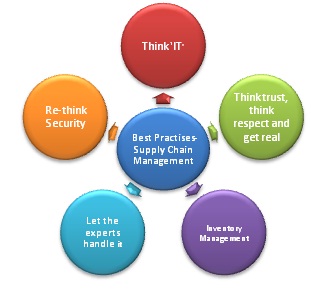

Think “IT”

The world is increasingly becoming flat and the way business is run is constantly changing. SCM has become global, complex and dynamic. In such a scenario, role of IT in SCM has become prominent.

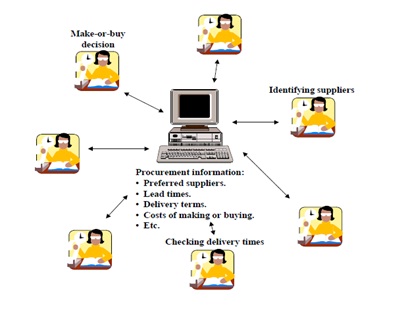

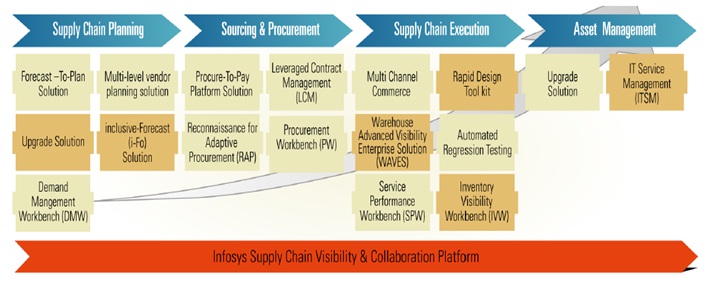

IT helps businesses redesign their SCM system by providing functional solutions for every step of the Supply Chain Management process; from Supply Chain Planning, Sourcing and Procurement, Supply Chain Execution and Asset Management. Use of customized business tools not only provides a central repository of information which helps all the departments in aligning their individual goals with that of the organization, but also automates the process. Integrating traditionally isolated systems like Product Data Management (PDM), Bill of Material (BOM), automated generation of orders, automated order processing and billing ensures that human factor is minimized which increases the efficiency of the entire SCM process.

Infosys, for instance, provides a suite of services only related to SCM but also to the business as a whole like Business Consulting, Modular Global Sourcing and Enterprise Application Integration. Its tools are present through all the stages of the SCM process. Its successful clients include IKON, IT Food Lion, and Hannaford Brothers among others.

Think trust, think respect and get real

The key to any successful relationship, supply chain or otherwise, is mutual trust. Sharing transactional data with suppliers and customers can lead to expanded sales opportunities for everybody.

Toyota shares product planning and proprietary cost information with its Tier One suppliers. It trusts its suppliers to meet its development and production deadlines. Thomas Stallkamp, head of Chrysler Corp. in 1990s introduced the idea of establishing a closer relationship with Chrysler’s own suppliers at his company and made Chrysler’s extended enterprise.

One of the key principles that Toyota follows is to respect its extended network of partners and suppliers by challenging them and helping them improve. Managers of supply chain need to reach out to critical suppliers and work on strengthening their business both to weather the crisis and increase profits for the future. OEMs should focus their efforts in developing meaningful relationships with their suppliers by putting in place performance metrics that drive the behaviours of the personnel who interface with suppliers. By this every OEM can improve its supplier relations to the benefit of both itself and its suppliers.

Recognize that not all of your suppliers are reliable in fulfilling orders on time and complete, and adjust your plans accordingly. Consumer packaged goods (CPG) giant Unilever decided in 2000 aimed to increase its asset utilization, lower inventories and improve customer service. It focused on improving its planning and forecasting process. It focussed on collaborating with a customer and agreeing on a forecast than having two or three internal forecasts. It helped in achieving 10% reduction in inventory, 10% improvement in forecast accuracy and a 5% increase in sales. Consulting firm Accenture, pointed out that each party in SCM needs to know each other. “If divorce is not an option and costs can’t fall much further, what happens next?” Perhaps it’s time for a better collaboration so that both parties get more out of it.

Inventory Management

The function of inventory includes storing transit stock, cycle stock, safety stock and anticipation stock. Supply chains are usually operated by independent agents with individual preferences. The decisions – when to order and how much to order are critical in determining the efficiency of an inventory management process. It depends on the level of inventory the company is keeping, whether it is minimum inventory level, safety stock or lead-time.

As such, the coordination of the activities of the various players involved in a supply chain process such as suppliers, manufacturers, and distributors becomes even more important. Proper inventory management results in smooth material flow and minimizes cost while meeting up to the customers’ demands. The order and demand forecasting is done with real time-time data from all the business processes such as production, sales, and scheduling. Strategic inventory management would not only ensure reduction of wasted inventory but also result in optimized performance and reduction in working capital.

Let the experts handle it

The increasing sophistication of supply chains spanning corporate departments and global boundaries has made it imperative that the companies take a closer look on every task, process, and operation within its enterprise. Because few companies actually have this expertise in-house, and fewer are willing to invest resources in nonstrategic areas, a new breed of third-party supply chain specialists has emerged. Much of the reason behind this is that companies are increasingly being challenged to focus on their core competencies. Many of the noncore tasks are now being outsourced to companies that specialize in offering these services. In fact, roughly 80 % companies in North America and around 70% in other industrial regions of the world are already using an outsourcer for at least one key supply chain task. These outsourcers, known in supply chain circles as 3PLs (third party logistics provider), have grown within the past decade to become a global market worth $200 billion in 2008, according to market research firm Armstrong & Associates. Major companies such as Ford Motor, General Motors, PepsiCo, Procter & Gamble, and Wal-Mart each use 30 or more 3PLs.

But before undertaking a 3PL agreement, a firm has to measure its own logistic performance to identify if 3PL is improving the logistics. This is done by ranking the 3PL across various parameters like cost, lead time, delivery time and identifying the root cause of any problem and by taking steps to correct them.

Re-think security

Security as an issue has come to light in recent years. Discounting natural disasters, other factors such as security breaches, terrorism, piracy and theft have caustic consequences on SCM. Various efforts have been taken by governments and international agencies to enhance the security of supply chain. The security measures focus on areas like Cargo Management, Facility Management, Information Management, Human Resources Management and Company Management

Some of the key supply chain security initiatives taken by international organizations include:

- The Customs Trade Partnership against Terrorism (C-TPAT), a voluntary compliance program to improve the security of corporate supply chains

- The World Customs Organization (WCO) adopted the Framework of Standards to Secure and Facilitate Global Trade in 2005, consisting of supply chain security standards for Customs administrations including Authorized Economic Operator (AEO) programs

- The Container Security Initiative(CSI), a program led by U.S. Customs and Border Protection in the Department of Homeland Security focused on screening containers at foreign ports

- The Global Trade Exchange a DHS data-mining program designed to collect financial information about shipments; with the objective of determining safety of cargo shipments are safe

Best-in-class companies constantly train and update their employees on disruption response procedures. The less vulnerable the company is to disruptions, the less susceptible it’ll be to daily market fluctuations as well.

Summing it up

In US alone, more than $1 trillion is spent every year on transportation, distribution and inventory management. The responsibility of managing that spending falls on the shoulders of supply chain professionals. The roles may differ but the goals are generally the same-develop and position the company’s supply chain to compete with global markets. Many of the biggest companies got to where they are thanks to their adoption of best practises to manage their world-class supply chains which require money, time, talent, energy, focus, commitment and guts.

This article has been authored by Vibhor Aggarwal and Pankaj Malhotra from IIFT.

Views expressed in the article are personal. The articles are for educational & academic purpose only, and have been uploaded by the MBA Skool Team.

If you are interested in writing articles for us, Submit Here

Share this Page on:

What is MBA Skool?About Us

MBA Skool is a Knowledge Resource for Management Students, Aspirants & Professionals.

Business Courses

Quizzes & Skills

Quizzes test your expertise in business and Skill tests evaluate your management traits

All Business Sections

Write for Us