- Business Concepts ›

- Operations and Supply Chain ›

- Design for Manufacture & Assembly (DFMA)

Design for Manufacture & Assembly (DFMA)

Definition & Meaning

This article covers meaning & overview of Design for Manufacture & Assembly (DFMA) from operations perspective.

What is meant by Design for Manufacture & Assembly (DFMA)?

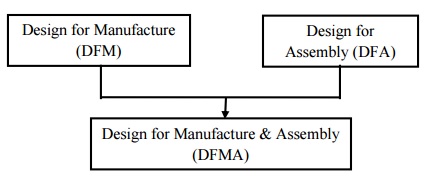

DFMA or Design for Manufacture and Assembly is framed by combining two methodologies, namely Design for Manufacture and Design for Assembly. Design for Manufacture refers to the design for ease of manufacture of the parts that will form a product while Design for Assembly refers to the design of the product for ease of assembly.

DFMA forms the basis guiding the design team in simplifying the structure of the product, thus reducing costs incurred in the manufacturing and assembly of the product. DFMA acts as an important measure for quantifying the improvements achieved in the designing of the product. It forms a component of Lean Manufacturing due to its functionality to identify, quantify and eliminate waste or inefficiency in a product design. It also functions as a tool enabling detailed comparison with competitor’s products and as the cost constraint calculator to support the negotiations with suppliers.

Advantages of applying DFMA include:

• It helps produce high performance, competitively priced product at a minimal cost

• It helps to reduce the time to market and quality of the product

• It helps analyse a design from assembly and manufacture point of view

• It helps in reduction of inventory and the subsequent costs involved

Hence, this concludes the definition of Design for Manufacture & Assembly (DFMA) along with its overview.

This article has been researched & authored by the Business Concepts Team which comprises of MBA students, management professionals, and industry experts. It has been reviewed & published by the MBA Skool Team. The content on MBA Skool has been created for educational & academic purpose only.

Browse the definition and meaning of more similar terms. The Management Dictionary covers over 1800 business concepts from 5 categories.

Continue Reading:

What is MBA Skool?About Us

MBA Skool is a Knowledge Resource for Management Students, Aspirants & Professionals.

Business Courses

Quizzes & Skills

Quizzes test your expertise in business and Skill tests evaluate your management traits

Related Content

All Business Sections

Write for Us