- Business Concepts ›

- Operations and Supply Chain ›

- Uptime

Uptime

Definition & Meaning

This article covers meaning & overview of Uptime from operations perspective.

What is meant by Uptime?

Uptime is the ratio of the total time during which a machinery or equipment is operational or the production time to the total available time, that is the total time for which the machinery or equipment is available.

It is the opposite of downtime, which is the ratio of the total time during which the machinery or equipment is non-operational to the total available time.

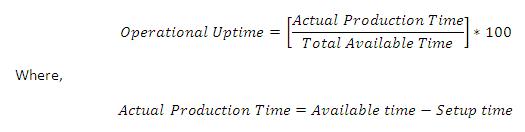

Formula: Operational uptime is expressed as a percentage and is calculated as follows –

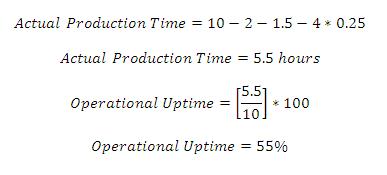

Example: Suppose the operations team at XYZ Corp. wants to use a machine for carrying out their day-to-day operations. The machine is available for a total of 10 hours every day. It takes around 2 hours to setup the machine, another 1.5 hours to set it back down, and needs to be allowed to cool down for 15 minutes after every 1.5 hours of production. The uptime of the machine will be calculated as follows –

This article has been researched & authored by the Business Concepts Team which comprises of MBA students, management professionals, and industry experts. It has been reviewed & published by the MBA Skool Team. The content on MBA Skool has been created for educational & academic purpose only.

Browse the definition and meaning of more similar terms. The Management Dictionary covers over 1800 business concepts from 5 categories.

Continue Reading:

What is MBA Skool?About Us

MBA Skool is a Knowledge Resource for Management Students, Aspirants & Professionals.

Business Courses

Quizzes & Skills

Quizzes test your expertise in business and Skill tests evaluate your management traits

Related Content

All Business Sections

Write for Us