- Business Concepts ›

- Operations and Supply Chain ›

- Failure Mode and Effect Analysis FMEA

Failure Mode and Effect Analysis FMEA

Definition & Meaning

This article covers meaning & overview of Failure Mode and Effect Analysis FMEA from operations perspective.

What is meant by Failure Mode and Effect Analysis FMEA?

Failure Mode and Effect Analysis (FMEA) is a systematic technique for failure analysis and involves following 10 steps:

1. Listing of the key process steps in the first column

2. Listing of potential failure mode for each step of the process, hence finding in what different ways could the process go wrong

3. Analyzing the failure mode and listing the effects of it

4. Analyzing and rating of the severity of the effects of failure mode. 1 represents not severe at all and 10 represents extremely severe

5. Identifying the cause of the failure and ranking it in the occurrence column, with 1 signifying highly unlikely chance of occurrence of the cause

6. Identifying the checks and controls to detect the issues and ranking them in terms of their effectiveness in detection column, 1 representing excellent controls

7. Multiplying the severity, occurrence and detection column ranks and filling this value in risk priority number (RPN) column.

8. Using RPN to identify critical issues to be focused

9. Coming up with action plan and carrying out the action

10. Once actions have been taken place, re analyzing and rescoring.

FMEA refers to a proactive approach of minimizing occurrence of potential failures in a product or process. There are two kinds of FMEA:

Design FMEA or D-FMEA: systems and subsystems are analyzed right in the early design phase and before release to production.

Process FMEA or P-FMEA: manufacturing or business processes are analyzed after they have been implemented.

The several steps involved in FEMA are as follows:

Identification of all potential failures

Assessment of risk involved with these failures

Assigning priority level to potential failures

Address the most important potential failure

There are two common methods to evaluate risk associated with potential failures:

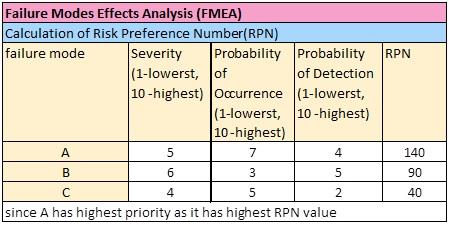

1. Risk Priority Numbers (RPNs): In this method, each potential failure is evaluated based on 3 parameters i.e. severity, occurrence and detection on the scale of 1-5 or 1-10 (where 1 = lowest and so on) and then, RPN is calculated using following formula,

RPN=Severity ×Occurrence ×Detection

It helps in prioritizing the potential failures in order to take corrective action.

2. Criticality Analysis: It has 2 types:

Qualitative criticality analysis: In this, criticality matrix is used in order to compare potential failures with severity on horizontal axis and occurrence on vertical axis.

Quantitative criticality analysis: Analysis team calculates reliability/unreliability of each item and find out how much portion of unreliability can be attributed to each potential failure. It also finds out probability that a potential failure mode may result in overall system failure.

The benefits of FEMA include improvement in designs and processes through corrective measures. It also results in increased reliability, enhanced customer satisfaction and reduction in maintenance costs. It can be done on a single paper or excel sheet. But it needs to comply with certain safety and quality measures i.e. six sigma, ISO 9001, Good Manufacturing Practices (GMPs) etc.

Hence, this concludes the definition of Failure Mode and Effect Analysis FMEA along with its overview.

This article has been researched & authored by the Business Concepts Team which comprises of MBA students, management professionals, and industry experts. It has been reviewed & published by the MBA Skool Team. The content on MBA Skool has been created for educational & academic purpose only.

Browse the definition and meaning of more similar terms. The Management Dictionary covers over 1800 business concepts from 5 categories.

Continue Reading:

What is MBA Skool?About Us

MBA Skool is a Knowledge Resource for Management Students, Aspirants & Professionals.

Business Courses

Quizzes & Skills

Quizzes test your expertise in business and Skill tests evaluate your management traits

Related Content

All Business Sections

Write for Us