- Business Concepts ›

- Marketing and Strategy ›

- Factory Pack

Factory Pack

Definition, Importance & Example

This article covers meaning & overview of Factory Pack from marketing perspective.

What is meant by Factory Pack?

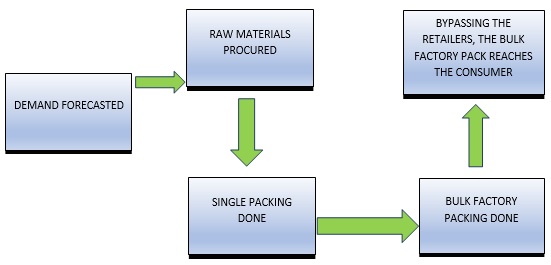

A factory pack is the packaging of one item, or more than one similar items, one normal & one expensive item. The packaging of factory pack is done at the factory and touches base in the exchange directly as of now in the limited time structure. Generally speaking, it is the packaging of an item and its distribution.

When it comes to factory packs customers would prefer it as it can be gained at wholesale prices and that the product comes in bulks and hence reduces the surplus charges incurred on the items when it comes through the chain. The packaging at the factory is basically done depending on the demand in the market of that product. This needs operational manifests and strategic marketing. Whenever a product is manufactured at the factory it is dependent on the forecasted demand for the product in the market and then comes the role of the marketing strategy wherein the packaging of the product is done keeping in demand the requirements of the factory packs.

Factory Pack Strategy

Factory packs can be explained from an operational perspective as well as a marketing & sales perspective.

1. Operations Aspect of Factory Pack: Here the assembly line is the lifeline. The product is manufactured depending on the forecasted demand in the market of the product. An analysis of the demand is done and then the assembly line is set in motion.

Now after the product is manufactured it comes down to the inventory level where the products are packed in bulks for the forecasted consumer base who have requisites for factory packs.

2. Marketing Aspect of Factory Pack: Here the marketing strategy comes into the picture. The product’s packaging is done depending on any analysis that is done. If the requirement of procurement of factory packs is more, then the packs are made respectively at the factory level and then they are packed in bulk so as to be sold in bulks.

Importance of Factory Pack

Packaging at the Factory is one of the most important levels at the assembly line. The packaging of a product decides many of the marketing strategies for the product. Let’s discuss a few:

1. Factory pack ensures that the target consumer has a high requirement of the product so that the product can be sold in bulks from the factory level.

2. If the product is a perishable good then packaging plays a major role as the packaging needs to be strong enough and perfect for ensuring a larger lifetime of the product. Hence this leads to ensuring no loss of inventory and hence the assembly line is designed in a way to pack the whole bulk in a stiff and strong form.

3. We all know that maximum people always judge a product by its pack. Making them aware of more choices and more no of products of the company that is available in bulk would greatly increase the revenue of the firm.

4. Next in line is the number of products that can be packed together leading to a larger amount on the orders by the retailers.

5. Nowadays the company charges premium prices based on the packaging of products.

Advantages of Factory Pack

Certain advantages of factory packs are:

1. Increased buying by the consumers- once the need for the product has been generated and if the requirement of the product has been forecasted to be in bulk then the industry would be benefitted.

2. Increased self-service has led to increased demand for packaging and this is very advantageous for the players in the market. As packaging of Bulk Products is a rising market for new players.

3. Next is the scope for innovation which increases three fold. With the rise for the demand for bulk packaged products, the market has seen a rise in the number of innovations in these fields. For example the no of products that can be purchased and hence to be packaged in turn generating maximum revenue rather than from the customary selling to wholesalers.

4. Now the major advantage is the product differentiation which is greatly achieved through the type of packaging. And in recent times, the Factory Pack industry has seen steady growth due to the increased demand for Bulk products.

Disadvantages of Factory Pack

A few drawbacks of factory packs are:

1. Cost disadvantage- We all do agree on the fact that packaging is important for a company’s product but packaging costs also levy a heavy toll on the company’s revenue as the packaging costs are high. As there needs to be the first packing of a single product and a combined packing of the Bulk Products.

2. Sometimes if the demand for the product falls and the products packed in bulk are in vain.

3. If the product has been packed in bulk at the factory and the customer finds that one of the product is a faulty one then the whole bulk is at a loss.

Example of Factory Pack

Swarovski Crystal is a company which provides its customers with an opportunity to purchase sparkling crystals at wholesale prices. These come directly from the Factory and have genuine crystals without being tampered. The motto over here is buy in bulk and save. This is the strategy that is required for the marketing of Factory Packs.

The assembly line of the factory is designed in a pattern so as to bulk up a number of products and the pack them together. This strategy reduces the gap between the manufacturer and the customer so that the customer gets the products at a cheaper rate and that too in bulk.

Hence, this concludes the definition of Factory Pack along with its overview.

This article has been researched & authored by the Business Concepts Team which comprises of MBA students, management professionals, and industry experts. It has been reviewed & published by the MBA Skool Team. The content on MBA Skool has been created for educational & academic purpose only.

Browse the definition and meaning of more similar terms. The Management Dictionary covers over 1800 business concepts from 5 categories.

Continue Reading:

What is MBA Skool?About Us

MBA Skool is a Knowledge Resource for Management Students, Aspirants & Professionals.

Business Courses

Quizzes & Skills

Quizzes test your expertise in business and Skill tests evaluate your management traits

Related Content

All Business Sections

Write for Us